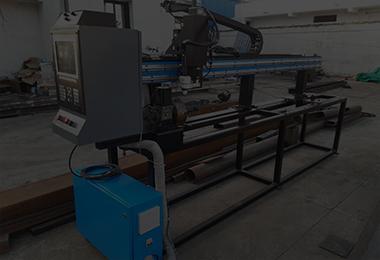

Features and Maintenance of CNC Plasma Cutting Machine

The functioning rule of the CNC plasma slicing machine is to utilize compacted air as the functioning gas, high-temperature and rapid plasma bend as the hotness source, and utilize advanced projects to drive the development of the machine apparatus. With the development of the machine device, the steel plate will be cut by the haphazardly prepared cutting device. The metal is somewhat dissolved and the softened metal is blown away with a fast wind stream simultaneously, framing a tight cut

Features of CNC Plasma Cutting Machine:

Safe Operation:

- The CNC cutting machine is a sort of accuracy hardware, so the activity of the cutting machine should be three fixed (a proper individual, fixed machine, fixed post.

- The administrator should be expertly prepared and have the option to dominate the basics of the activity, non-experts ought not move.

- Preceding the activity, it should be affirmed that there is no outer obstruction. After everything is ordinary, balance the cut plate on the cutting stage, and the plate can’t surpass the cutting reach.

Everyday Maintenance:

- The soil on the machine instrument and guide rails should be cleaned each functioning day to keep the machine bed clean. The air source and power supply should be wound down when off work and the leftover air in the machine apparatus pipe belt should be depleted.

- Assuming that you leave the machine for quite a while, turn off the ability to forestall non-proficient activity.

- Focus on see whether there is greasing up oil on the outer layer of the machine’s flat and longitudinal aide rails and racks to keep them all around greased up!

Weekly Maintenance:

- The machine ought to be tidied up consistently, the even and vertical aide rails, transmission gear racks, and greasing up oil ought to be added.

- Check whether the flat and vertical rail wipers work typically, and supplant them on schedule in the event that they are unusual.

- Check whether every one of the cutting lights are free, tidy up the waste of the start gag, and keep the start ordinary.

- If a programmed tallness change gadget is joined, check whether it is delicate and regardless of whether to supplant the test.

- Check whether the plasma cutting spout and cathode are harmed and regardless of whether the slicing spout and anode should be supplanted.

Monthly Maintenance:

- Actually look at whether there is refuse at the primary air bay and regardless of whether every valve and tension measure is working appropriately.

- Check whether all air pipe joints are free and all lines are not harmed. Fix or supplant it if essential.

- Check whether all transmission parts are free, actually look at the cross section of cog wheels and racks, and make changes if important.

- Relax the cinching gadget and move the pulley by hand to check whether it comes and go uninhibitedly. On the off chance that there is any irregularity, change or supplant it on schedule.

- Check the clasping block, steel belt, and guide wheel for detachment and snugness of the steel belt, and change if fundamental.

- The functioning site and work space of the CNC cutting machine are somewhat unforgiving, and the metal residue is moderately huge. Subsequently, the machine should be totally cleaned and kept up with, and a devoted individual ought to be answerable for the grease, fix, and support of the hardware!

Products

Latest Blogs