- 917, 9th Floor, The Capital-2, Science City Road, Sola, Ahmedabad-380060. Gujarat (INDIA)

- metweld3@gmail.com

- info@metweld.in

- metweld3.sales@gmail.com

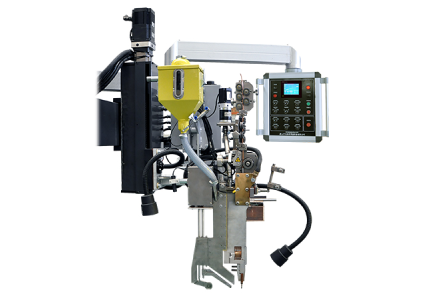

| Specification | |

|---|---|

| Max. weld thickness | 400mm |

| Groove angle | 1°~2° |

| Groove width | 18-30mm(18-22mm at bottom)1°~2° |

| Pass No. per layer | Two passes(One pass at first layer) |

| Wire diameter | 3.0/4.0mm |

| Wire feed speed | 60~180mm/min |

| Deposition speed | 5~10kg/h |

| Torch oscillating rangeGroove width | ≤±3.5° |

| Torch oscillating precision | ≤±0.5° |

| Horizontal tracking precision | ≤±0.2mm |

| Vertical tracking precision | ≤±0.5mm |

| Cross slide strokes | 300*400mm |

| Highest heated temperature | 350℃ |

| Min. diameter for internal welding | 1500mm |

Since the year 1982, MET WELD holds a strong presence and offered a comprehensive range of CNC Plasma Cutting Machine and Welding, Cutting Equipment in various sectors of industry.