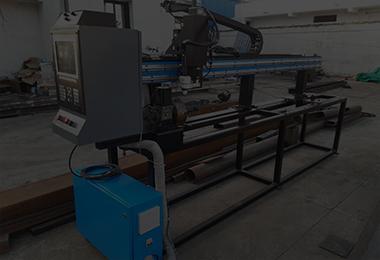

CNC Plasma Cutting alludes to the cutting of metals utilizing a PC controlled plasma torch. Plasma cutters work by driving gas or compacted air through a spout at high velocity. When an electric circular segment is brought into the gas, ionized gas or plasma is framed, the fourth condition of issue. This, thusly, slices through the metal.

CNC plasma cutters shift broadly in value, size and functionalities. Machines that slice metals at speeds up to 500 inches each moment are exceptionally precise and quick cutting. Plasma cutting machines give a quality work and Plasma cutters require plasma gas and a helper gas to capacity, and they shift and distinctive as per the material to be cut.

The machine needs a region around it as a cradle for any sort of sparkle. Essentially, the floor ought to be of concrete or other fire safe material.

The Computer frameworks require gas or blower just as space. To forestall the plasma circular segment from meddling with the PC, the machine should be grounded, and the PC should be on a uninterruptible power supply (UPS) to guarantee ceaseless dependable power.

In the event that you intend to introduce your own CNC plasma shaper, ensure your shop’s power source is satisfactory (per details). Plans for the DIY CNC Plasma Table can be viewed as on Intractable.

If you want to get best quality and top models of CNC Plasma cutting machine, then METWELD is your solution that provides CNC Plasma cutting machine with advanced technologies.