As industries expand and manufacturing requirements become more sophisticated, cutting solutions must evolve. Precision, speed, and flexibility are no longer optional – they’re essential for producing high-quality components. Whether you’re working on automotive parts, construction materials, or heavy machinery, having the right cutting equipment can streamline operations and enhance productivity.

Three cutting machines that stand out for their precision and reliability are the CNC Plasma Cutting Machine, CNC Laser Cutting Machine, and Table type CNC Plasma Cutting Machine.

The CNC Plasma Cutting Machine is widely used for cutting thick metal sheets with high speed and precision. Its ability to handle materials like stainless steel, aluminum, and copper makes it a staple in industries such as shipbuilding, infrastructure, and heavy equipment manufacturing.

The process uses an ionized gas stream to cut through metals without direct contact, reducing wear and tear while ensuring smooth edges. This machine is especially suited for operations that require thick plate cutting without compromising on speed.

For industries where aesthetics, fine detailing, and smooth finishes are critical, the CNC Laser Cutting Machine is the perfect choice. It offers micron-level precision, making it ideal for cutting complex shapes and patterns in thin to medium materials.

It’s extensively used in aerospace, electronics, and signage fabrication, where even the smallest imperfection can affect performance or appearance. The laser beam creates clean edges with minimal heat-affected zones, reducing material distortion.

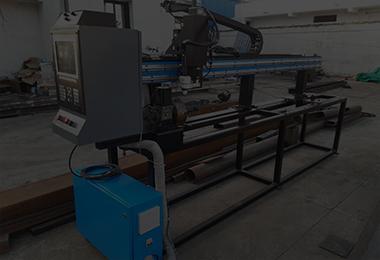

Small workshops and fabrication units often face space and budget constraints. The Table type CNC Plasma Cutting Machine offers a practical solution by combining a compact footprint with high cutting capacity.

This machine is easy to operate, making it suitable for medium-sized projects and prototype work. It’s an excellent entry point for businesses that need reliable cutting technology without investing in larger, more complex systems.

For manufacturers striving to stay competitive, investing in cutting equipment that balances precision, speed, and cost is crucial. The CNC Plasma Cutting Machine, CNC Laser Cutting Machine, and Table type CNC Plasma Cutting Machine offer complementary solutions that address various fabrication challenges. By integrating these tools into your workflow, you can achieve higher efficiency, reduce material waste, and maintain superior product quality.