Not all fabrication projects are created equal. Some require large-scale, high-volume production, while others demand mobility and quick turnaround. Choosing cutting machines that match your project’s scale and complexity can make a significant difference in operational efficiency.

Three machines that offer unmatched flexibility are the Gantry type CNC Plasma Cutting Machine, Portable CNC Plasma Cutting Machine, and Multi torch CNC Plate Cutting Machine.

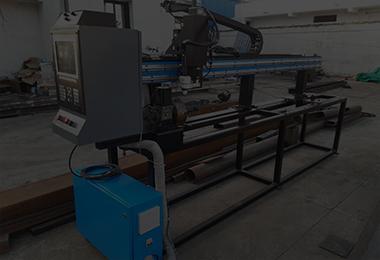

The Gantry type CNC Plasma Cutting Machine is designed to handle larger materials and more demanding projects. With its wide frame and robust structure, it allows cutting of longer sheets and heavier plates, making it ideal for industries like shipbuilding, structural steel fabrication, and heavy construction.

Its design ensures stability during operation, which results in consistent accuracy across extended cutting paths. This machine is perfect for facilities that process large batches or oversized components regularly.

Flexibility is essential when working in varied environments. The Portable CNC Plasma Cutting Machine is compact, easy to transport, and quick to set up at job sites, providing the freedom to perform cutting tasks wherever needed.

Whether you’re working on construction sites, pipelines, or remote facilities, this machine eliminates the need for fixed installations without compromising on cutting efficiency. It’s especially useful for maintenance teams that require reliable equipment in challenging conditions.

When projects involve repetitive cutting tasks, speed and uniformity are critical. The Multi torch CNC Plate Cutting Machine allows operators to cut multiple plates at once, reducing production time while maintaining precision.

This machine is widely used in fabrication units where meeting deadlines and maximizing output are essential. Its ability to maintain consistency across large cutting jobs makes it a game-changer in high-demand environments.

Whether your work involves large industrial sheets, on-site cutting, or high-volume production, the right equipment ensures that your operations remain efficient and cost-effective. The Gantry type CNC Plasma Cutting Machine, Portable CNC Plasma Cutting Machine, and Multi torch CNC Plate Cutting Machine each serve a specific purpose, offering flexibility and performance tailored to modern fabrication demands.