The rise of Pre-Engineered Buildings (PEB) has revolutionized industrial and commercial construction. Designed for efficiency, durability, and cost savings, PEB structures depend heavily on precision steel fabrication — and that’s where CNC Plasma Cutting Machines play a vital role.

By integrating CNC (Computer Numerical Control) technology with plasma cutting, industries can achieve the perfect combination of speed, accuracy, and scalability — three essential factors that define the success of every PEB project.

PEB construction involves multiple steel components such as columns, rafters, purlins, trusses, and base plates, which must fit together precisely during assembly. Any deviation in cutting dimensions can lead to alignment issues and compromise structural integrity.

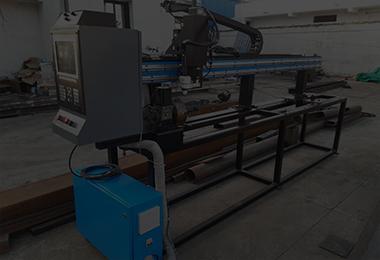

Manual cutting methods no longer meet modern accuracy and speed requirements. CNC Plasma Cutting Machines automate this process, delivering precision, repeatability, and consistency across every cut — whether working with a 5 mm sheet or a 50 mm plate.

Key benefits for PEB fabrication include:

PEB fabrication often involves cutting heavy and medium-thick steel plates — making CNC plasma cutting the ideal choice. Unlike laser systems that excel with thin sheets, plasma machines handle medium-to-thick plates efficiently and cost-effectively.

PEB projects demand quick turnaround. CNC plasma cutters offer high-speed cutting of large beams, columns, and rafters, ensuring faster production and streamlined workflows.

These machines ensure high accuracy and clean edge finishes, even on thicker structural steel, aluminum, or carbon steel — improving weld quality and assembly fitment.

CNC plasma systems enable custom geometries, slotting, and hole patterns directly from CAD drawings, allowing design flexibility without manual intervention.

Compared to laser systems, plasma cutters have lower capital and maintenance costs, making them ideal for PEB manufacturers prioritizing durability and affordability.

Metweld’s CNC Plasma Machines integrate effortlessly with CAD/CAM software, reducing manual programming errors and simplifying workflow from design to fabrication.

CNC plasma cutting technology plays a key role across various stages of PEB fabrication and erection, ensuring precision and efficiency in every component.

Used for precise cutting of columns, rafters, and purlins to maintain dimensional accuracy and alignment during on-site assembly.

Ideal for fabricating base plates, end plates, and connection components that require tight tolerances for drilling and welding.

Ensures accurate hole placements and edge finishes for bracings and gussets, critical for structural stability and reinforcement.

Handles varying plate thicknesses to produce roof cladding supports and other architectural steel elements with precision.

Ideal for creating complex shapes used in canopies, mezzanine floors, and curved steel designs with uniform accuracy and finish.

Incorporating CNC Plasma Cutting Machines in PEB manufacturing offers measurable advantages across operations.

Automation and precision enable high-speed cutting with reduced human intervention — improving overall production throughput.

Advanced torch design ensures smooth, burr-free edges, minimizing post-processing requirements.

Smart nesting software optimizes layout efficiency, reducing material scrap and improving yield.

Metweld CNC systems support both plasma and oxy-fuel cutting — adapting to diverse material thicknesses.

Precision-driven automation ensures identical output, supporting PEB standardization and faster on-site assembly.

Reduced consumables, energy efficiency, and minimal human error lead to long-term operational savings.

| Parameter | CNC Plasma Cutting | Laser Cutting | Oxy-Fuel Cutting |

| Material Thickness | Medium to thick (up to 50 mm) | Thin to medium (up to 25 mm) | Thick (>50 mm) |

| Cutting Speed | Fast for thick plates | Very fast for thin sheets | Slow |

| Edge Quality | Smooth and clean | Excellent | Rough; requires finishing |

| Cost Efficiency | High | Moderate to low | Low setup, high consumables |

| PEB Applications | Columns, rafters, base plates | Gussets, brackets | Heavy beams and base plates |

Plasma cutting offers the best balance of cost, performance, and flexibility — making it the preferred choice for PEB manufacturing facilities worldwide.

Metweld provides a complete range of CNC Plasma Cutting Machines tailored to meet the demands of modern PEB manufacturers.

By adopting Metweld’s advanced plasma systems, PEB manufacturers can achieve superior productivity, precision, and profitability while maintaining world-class quality standards.

In the world of Pre-Engineered Buildings, precision defines performance. CNC Plasma Cutting Machines simplify complex fabrication processes, helping industries meet deadlines faster without compromising quality.

With Metweld’s CNC Plasma Cutting solutions, PEB manufacturers can transform how they cut, assemble, and deliver — saving time, cost, and effort in every project.