In the world of metal fabrication, efficiency and precision are non-negotiable. One of the most versatile tools that has transformed the industry is the CNC Plasma Cutting Machine. From small workshops to large-scale manufacturing units, these machines ensure faster cutting, consistent quality, and cost savings.

But with so many models available, how do you choose the right one? Let’s explore the main types of CNC Plasma Cutting Machines and their applications.

The Gantry Type CNC Plasma Cutting Machine is designed for heavy-duty industrial use. It is ideal for cutting thick steel plates and handling large sheets with ease. Its robust structure ensures stability, accuracy, and long working life, making it the top choice for large fabrication companies.

Compact yet powerful, the Portable CNC Plasma Cutting Machine is a favorite among small workshops and on-site fabrication projects. It delivers precise cuts, requires less space, and is affordable compared to larger models.

The Table Type CNC Plasma Cutting Machine is highly efficient for medium-scale operations. With a fixed table and plasma torch, it is suitable for cutting smaller sheets with speed and precision. Its stability ensures consistent quality and minimal errors.

If you’re looking to maximize output, the Multi Torch CNC Plate Cutting Machine is the solution. Equipped with multiple cutting torches, it allows simultaneous cutting of several parts, significantly reducing production time and costs.

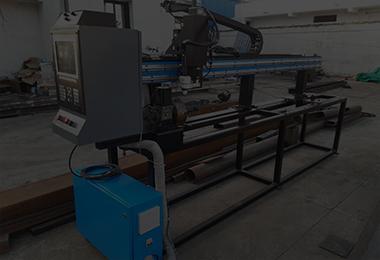

For businesses that work with both flat plates and cylindrical pipes, the CNC Plasma Plate & Pipe Cutting Machine is the perfect hybrid solution. It offers the flexibility to cut diverse shapes and materials, making it ideal for industries like construction, shipbuilding, and pipelines.

Investing in the right CNC Plasma Cutting Machine depends on your production requirements, materials, and scale of operations.

By selecting the right model, you can ensure greater efficiency, lower costs, and consistent quality for your fabrication business.