If you are new to the fabrication industry or planning to invest in modern cutting technology, understanding CNC Plasma Cutting Machines and CNC Laser Cutting Machines can feel overwhelming. This guide will walk you through the basics, how they work, their applications, and which one might be the right fit for your business.

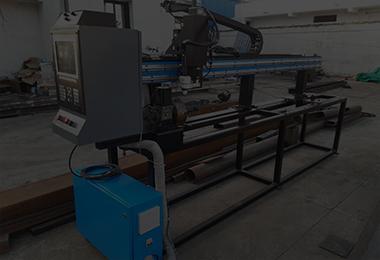

A CNC Plasma Cutting Machine uses a high-temperature plasma arc to cut through conductive metals like steel, stainless steel, and aluminum. Controlled by computer numerical control (CNC) software, it ensures accurate, repeatable, and efficient cuts.

A CNC Laser Cutting Machine uses a focused laser beam to melt or vaporize material, delivering unmatched precision. A specialized form, the Fiber Laser Cutting Machine, is widely popular for its speed, energy efficiency, and ability to cut thin to medium-thick materials with intricate detail.

Whether you choose plasma or laser, CNC cutting machines ensure:

For beginners, starting with the right machine is crucial. Evaluate your material type, thickness, budget, and production requirements before making a decision.

The world of CNC technology may seem complex, but with the right guidance, choosing between a CNC Plasma Cutting Machine and a CNC Laser Cutting Machine becomes simple. Both technologies have transformed industries by improving efficiency, reducing costs, and delivering superior quality.

If you’re just starting your journey, take time to analyze your needs, explore different machine types, and invest in the right technology that aligns with your business goals.