In today’s competitive manufacturing and fabrication world, precision, speed, and efficiency are no longer optional – they are essential. Among modern cutting technologies, the CNC Laser Cutting Machine has emerged as one of the most reliable solutions for industries requiring high accuracy and superior finish.

Whether you’re working in automotive, sheet metal fabrication, or signage manufacturing, CNC laser technology offers unmatched performance. Let’s dive deeper into what makes CNC laser cutting machines, especially fiber laser cutting machines, the preferred choice across industries.

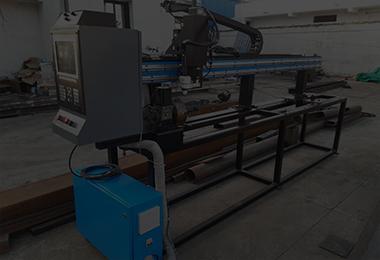

A CNC Laser Cutting Machine is a computer-controlled system that uses a focused laser beam to cut or engrave materials such as steel, stainless steel, aluminum, brass, acrylic, and more.

Unlike traditional methods, laser cutting doesn’t require direct physical contact. Instead, the machine follows a programmed design with micron-level accuracy, ensuring flawless results every single time.

The shift from conventional cutting methods to CNC laser technology is driven by several factors:

From small workshops to large-scale manufacturing plants, industries prefer MetWeld’s CNC laser machines for their reliability and flexibility.

CNC Laser Cutting is revolutionizing industries such as:

Both CNC Plasma Cutting Machines and CNC Laser Cutting Machines are widely used, but they serve different purposes:

If you need clean, intricate, and high-quality cuts, CNC laser cutting is the better choice. For bulk cutting of thick plates, plasma machines are more suitable.

When choosing a CNC Laser Cutting Machine, consider these key factors:

The CNC Laser Cutting Machine, especially the fiber laser cutting machine, is reshaping industries by offering precision, speed, and cost-effectiveness. Compared to plasma cutting, it provides cleaner finishes and is perfect for applications where accuracy is non-negotiable.

If you are planning to invest in CNC laser cutting technology, choosing the right partner like MetWeld is crucial. With the right machine, your business can achieve higher productivity, reduced waste, and superior quality output.