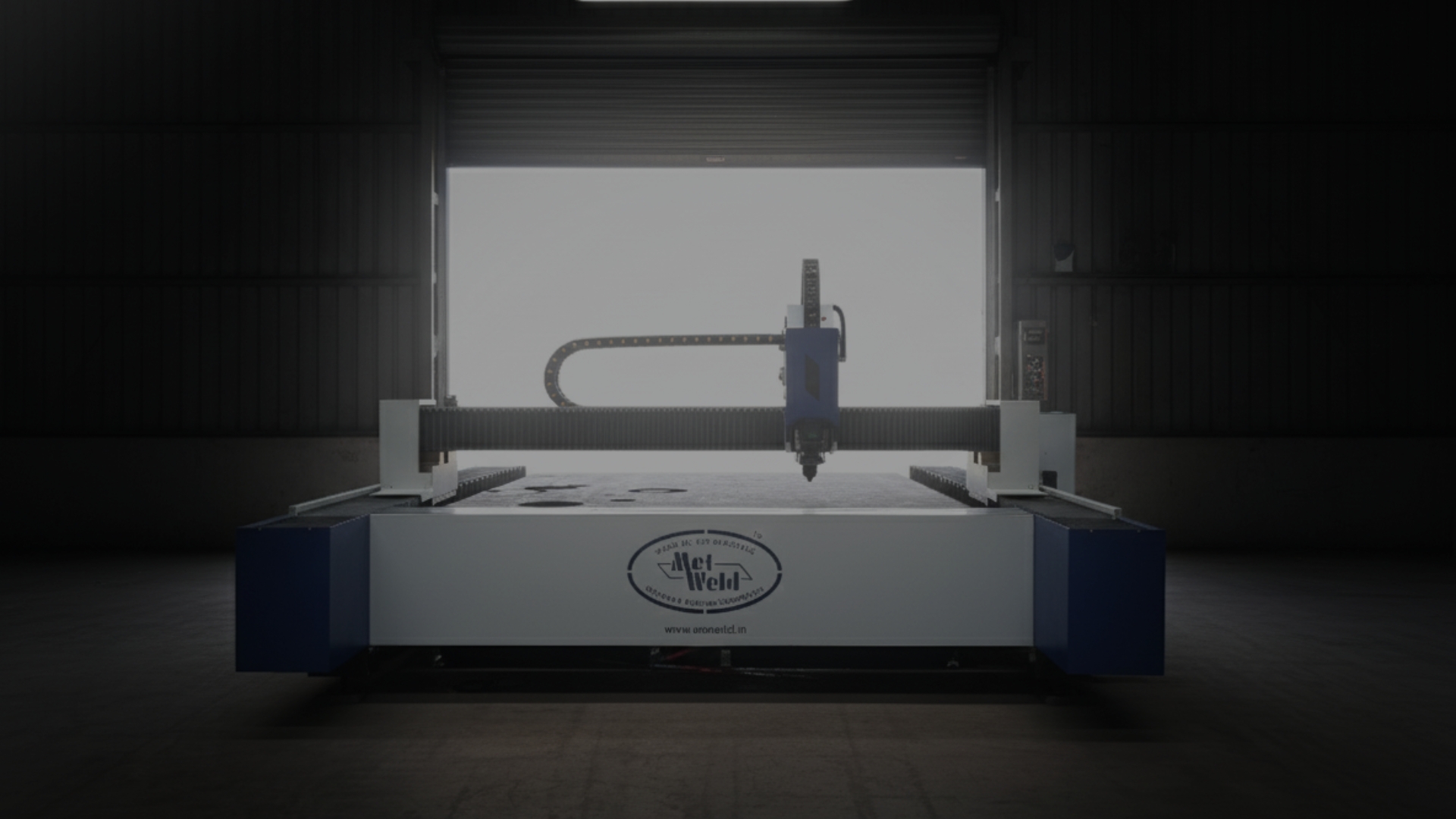

In industries where thick metal plates, large components, and continuous production are the norm, cutting technology must deliver power, speed, and reliability. This is where CNC Plasma Cutting Machines play a crucial role. Designed specifically for heavy-duty industrial applications, these machines offer an ideal balance between cutting performance and cost efficiency.

From fabrication workshops to shipyards and PEB manufacturing units, CNC plasma cutting has become an essential solution for processing medium to thick metals accurately and efficiently.

A CNC plasma cutting machine uses a high-velocity jet of ionized gas (plasma) to cut through electrically conductive materials. The plasma arc reaches extremely high temperatures, allowing it to melt metal quickly while the CNC-controlled motion system ensures precise cutting paths.

Unlike manual plasma cutting, CNC automation enables consistent accuracy, repeatability, and the ability to execute complex shapes directly from CAD designs. This makes plasma cutting suitable not only for rough cuts but also for precision industrial fabrication.

Heavy industries often deal with thick plates, structural steel, and large-format materials. CNC plasma cutting machines are engineered to handle these requirements efficiently.

Key advantages include:

Plasma cutting performs exceptionally well on carbon steel, stainless steel, and aluminum, making it versatile for industrial use.

Modern CNC plasma cutting machines are equipped with advanced controllers that regulate torch height, cutting speed, and arc stability. These features help maintain consistent cut quality across varying plate thicknesses.

With CNC automation, manufacturers achieve:

This level of precision is especially important in sectors where structural integrity and fitment are critical.

CNC plasma cutting machines are widely used in multiple industrial sectors due to their power and flexibility.

Common applications include:

Their ability to handle large plates and complex profiles makes CNC plasma systems indispensable in heavy fabrication environments.

One of the strengths of CNC plasma technology is its adaptability. Manufacturers can choose from various configurations depending on production needs, such as:

This flexibility allows industries to scale production efficiently without changing core cutting technology.

Compared to laser cutting systems, CNC plasma cutting machines require lower initial investment and are more economical for cutting thicker materials. Consumables are cost-effective, and modern torch designs extend service life, reducing downtime.

Additional benefits include:

These factors make CNC plasma cutting a practical choice for industries focused on throughput and profitability.

Heavy industries operate in challenging environments with dust, heat, and long production hours. CNC plasma cutting machines are built with rigid frames, heavy-duty rails, and industrial-grade components to ensure reliable performance under demanding conditions.

This durability ensures consistent output, minimal breakdowns, and longer machine life — essential for uninterrupted industrial operations.

CNC Plasma Cutting Machines are a powerful solution for heavy-duty industrial applications where thickness capability, speed, and cost efficiency are key priorities. With the ability to process large steel plates accurately and consistently, they play a vital role in fabrication, construction, shipbuilding, and PEB manufacturing.

For industries seeking a reliable, scalable, and cost-effective cutting solution, CNC plasma cutting remains one of the most practical technologies in modern industrial manufacturing.