The Indian manufacturing industry is undergoing a technological revolution — one that’s driven by automation, precision, and efficiency. Among the innovations reshaping modern fabrication, the CNC Fiber Laser Cutting Machine stands out as a game-changer.

From automotive and construction to aerospace and fabrication, industries across India are replacing traditional cutting methods with fiber laser technology. Why? Because it delivers faster, cleaner, and more precise results — helping manufacturers meet global standards while keeping production costs under control.

India’s growing economy has led to an increased demand for high-quality, export-grade manufacturing. Components now require tighter tolerances, smoother finishes, and higher repeatability — something that older CO₂ or plasma systems can’t always achieve.

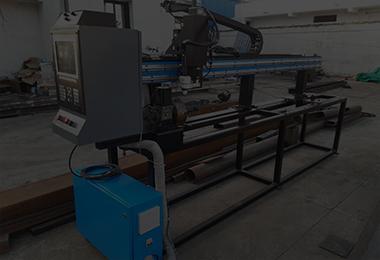

Enter the CNC Fiber Laser Cutting Machine, a system built to handle complex, high-speed operations with micron-level accuracy. These machines use fiber laser beams to cut through metals like stainless steel, mild steel, aluminum, brass, and copper with unmatched precision and efficiency.

Manufacturers that once relied on manual cutting, oxy-fuel systems, or CO₂ lasers are now investing in fiber laser cutting to modernize their processes — achieving better productivity and consistency.

Fiber laser machines produce a focused beam that allows for fine detailing and clean edge finishes — no burrs, no rough edges, and no secondary finishing needed.

CNC fiber lasers can cut thin and medium-thickness materials up to 3–4 times faster than traditional methods, boosting production output and reducing lead time.

Fiber laser systems consume less electricity and use no gas for beam generation, making them eco-friendly and cost-effective compared to CO₂ lasers.

With fewer moving parts and no mirrors or lenses in the beam path, these machines require minimal maintenance and deliver long operational life.

Built on stable frames with minimal vibration, ensuring consistent results even in 24/7 industrial operations.

In short, CNC Fiber Laser Cutting Machines offer speed, accuracy, and sustainability — the three critical pillars for the future of Indian manufacturing.

As competition grows and quality standards tighten, fiber laser cutting has become the preferred solution for forward-thinking industries. Here’s how it transforms operations across the manufacturing landscape:

Indian manufacturers catering to export markets require high dimensional accuracy and smooth finishes. Fiber laser machines ensure every cut meets international quality benchmarks.

Reduced material wastage, lower consumable use, and minimal rework translate into significant cost savings — ideal for both small workshops and large-scale factories.

High-speed cutting and automation reduce project timelines, helping businesses deliver orders on time — a major competitive edge in India’s fast-paced market.

From thin stainless sheets to 25 mm steel plates, fiber lasers cut a wide variety of metals with equal ease — making them suitable for fabrication, automotive, and construction sectors alike.

With no harmful gases or heavy consumables involved, fiber laser technology supports sustainable and green manufacturing — aligning with India’s “Make in India” and “Zero Waste” initiatives.

The versatility of CNC fiber lasers allows them to be used across multiple sectors in India’s growing industrial ecosystem:

Laser cutting is used to manufacture brackets, frames, enclosures, and custom sheet metal designs with high repeatability.

From chassis parts to exhaust components, fiber lasers ensure accuracy and smoothness for mass production lines.

Used for structural steel, decorative facades, stair railings, and custom design elements with aesthetic precision.

Ideal for cutting enclosures, switchboard panels, and intricate electrical housings.

Plays a key role in cutting components for solar panel frames, wind turbine structures, and power storage systems.

Delivers precise cuts on high-strength alloys like titanium and aluminum without thermal deformation — critical for aviation and defense manufacturing.

| Parameter | Fiber Laser Cutting | CO₂ Laser Cutting | Plasma Cutting |

|---|---|---|---|

| Precision | ±0.05 mm | ±0.2 mm | ±0.3 mm |

| Speed | Fast (thin–medium sheets) | Moderate | Fast (thick plates) |

| Material Range | Steel, SS, Copper, Brass, Aluminum | Steel, SS | Conductive metals |

| Maintenance | Very Low | High | Medium |

| Power Efficiency | 30% higher | Lower | Moderate |

| Operating Cost | Low | High | Medium |

| Best For | Precision fabrication | Medium-thickness cutting | Heavy plates |

While plasma remains the top choice for thick plate cutting, fiber laser is the leader in precision metal processing — especially for small to medium thickness applications.

Gujarat has rapidly evolved into one of India’s strongest industrial states, home to major automotive, fabrication, and engineering clusters in Ahmedabad, Vadodara, Rajkot, and Surat.

As industries upgrade their manufacturing capabilities, there’s an increasing demand for CNC Fiber Laser Cutting Machines that combine reliability, automation, and performance.

Metweld, as a Gujarat-based manufacturer, is leading this transition — delivering cutting-edge fiber laser technology to help local industries achieve global manufacturing standards.

Metweld is a trusted CNC Fiber Laser Cutting Machine Manufacturer in Gujarat, known for engineering robust and efficient systems for industrial use.

• High-Performance Fiber Laser Sources: Delivering consistent cutting quality.

• Automation & Nesting Software Integration: Reducing wastage and manual effort.

• Multiple Power Options (1kW–12kW+): Suitable for all material thicknesses.

• Durable Machine Build: Designed for 24/7 operation in Indian factory environments.

• Local Support & Service Network: Installation, training, and after-sales assistance across India.

By combining international-grade quality with local engineering expertise, Metweld empowers Indian manufacturers to produce more efficiently and competitively.

As India moves toward becoming a global manufacturing powerhouse, precision and efficiency will define success. Fiber laser cutting aligns perfectly with this vision — offering speed, sustainability, and quality that meets international demands.

In the coming years, CNC Fiber Laser Cutting Machines will play an even greater role in:

• Automation and Industry 4.0 integration

• Reducing human dependency in fabrication

• Enhancing quality control and consistency

Companies adopting this technology early will stay ahead of competitors in both domestic and export markets.

The rise of CNC Fiber Laser Cutting Machines marks a new era in Indian manufacturing — one defined by precision, productivity, and performance. From small workshops to industrial giants, every manufacturer looking to improve quality and efficiency can benefit from adopting fiber laser technology.

Metweld continues to lead this transformation as a trusted manufacturer and technology partner, delivering solutions that empower Indian industries to compete globally.