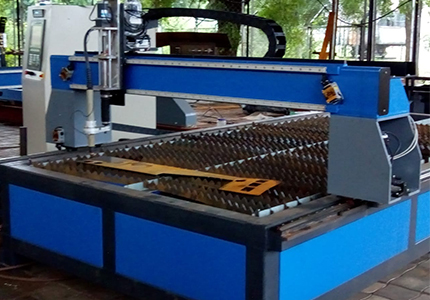

A Table Type CNC Plasma Cutting Machine is one of the most efficient and reliable solutions for precision metal cutting in modern fabrication. Built on a stable table structure, these machines are designed for accurate, high-speed cutting of sheet metals and plates. Unlike portable models, the table type design ensures rigidity, vibration-free operation, and better accuracy, making it ideal for industries that require consistent and repeatable results.

These machines are widely used in fabrication shops, automotive workshops, construction, and heavy industries where medium to thick plate cutting is essential. By integrating advanced CNC controls with robust plasma technology, they provide manufacturers with a cost-effective way to achieve precise cuts while maintaining high productivity.

Metweld’s table type CNC plasma systems are designed with durability, accuracy, and ease of use in mind. The stable table-based construction ensures that even during heavy-duty cutting, the machine delivers consistent performance without vibrations.

Key features include:

1. Rigid Table Design – Ensures stable cutting performance and better precision compared to portable or gantry-style machines.

2. High Cutting Accuracy – Achieves precise cuts with minimal taper, making it suitable for complex profiles.

3. Heavy-Duty Plasma Torch – Built for long operating hours and capable of handling thick plates with ease.

4. CNC Automation – Equipped with user-friendly CNC software for programming and executing intricate designs.

5. Material Versatility – Cuts stainless steel, mild steel, aluminum, and other conductive metals effectively.

6. Efficient Nesting Software – Reduces material wastage by optimizing sheet layouts for multiple profiles.

7. Compact & Floor-Saving Design – Occupies less space compared to gantry machines, making it perfect for workshops with space limitations.

8. Reduced Setup Time – Quick installation and calibration ensure faster project turnaround.

9. Optional Dual Cutting – Some models support both plasma and oxy-fuel cutting for added flexibility.

In addition to these, the dust and fume extraction systems can be integrated to maintain a cleaner working environment, ensuring both operator safety and machine longevity.

The applications of table type CNC plasma cutting machines cover a wide range of industrial and commercial uses.

In the fabrication industry, these machines are widely used for producing components such as brackets, frames, and sheet profiles with precision. The ability to cut both thin sheets and medium-thickness plates makes them highly versatile.

In automotive and heavy equipment manufacturing, table type plasma machines help produce chassis parts, custom body components, and parts for trucks, buses, and agricultural machinery.

Some of the key applications include:

• Construction & Infrastructure – Cutting steel beams, columns, and plates used in building and bridge structures.

• Shipbuilding – Processing large plates and profiles for ship hulls, decks, and marine equipment.

• Railways – Producing wagon and locomotive parts with accurate dimensions.

• Metal Art & Signage – Creating decorative panels, logos, and custom signs with precision cutting.

• Energy Sector – Fabrication of parts for wind energy, oil & gas, and renewable power systems.

By combining stability, accuracy, and speed, table type CNC plasma machines are suitable for industries that demand reliable production capacity while keeping operational costs under control.

When it comes to CNC plasma technology, Metweld is recognized as a trusted manufacturer delivering global-standard machines tailored to meet industrial requirements.

Here’s why industries prefer Metweld:

• Superior Build Quality – Machines are designed with robust table structures for long-term durability and accuracy.

• Advanced CNC Controls – Intuitive software allows easy programming, making it operator-friendly even for beginners.

• Customizable Configurations – Available in multiple bed sizes and power capacities to match production needs.

• High ROI – With efficient performance, reduced rework, and longer consumable life, Metweld machines lower per-part costs.

• Comprehensive Support – From installation and training to after-sales service and spare parts, Metweld provides complete lifecycle support.

• Proven Industrial Experience – Trusted across industries such as fabrication, construction, energy, and automotive.

Metweld’s machines are more than just cutting systems—they are production solutions that help businesses improve efficiency, reduce costs, and meet growing market demands.

1. Accuracy & Stability – The table design ensures vibration-free, precise cutting.

2. Cost-Effective Operation – More affordable than CNC laser cutting while delivering excellent performance for medium to thick plates.

3. Flexibility in Applications – Suitable for industries ranging from fabrication to shipbuilding.

4. High Productivity – Fast cutting speeds improve project delivery timelines.

5. Optimized Material Usage – Nesting software minimizes scrap and improves cost efficiency.

These advantages make them the preferred choice for businesses that want industrial-grade performance in a compact, cost-efficient setup.

| Process | Gas Cutting, Plasma Cutting |

|---|---|

| Effective cutting width | 1.25 m to 2 m |

| Effective cutting length | 2.5 m to 4 m |

| Positioning speed | 0 – 12,000 mm/min |

| Cutting thickness | 0.5 mm – 20 mm MS by plasma cutting 1 mm – 18 mm SS by plasma cutting |

Since the year 1982, MET WELD holds a strong presence and offered a comprehensive range of CNC Plasma Cutting Machine and Welding, Cutting Equipment in various sectors of industry.