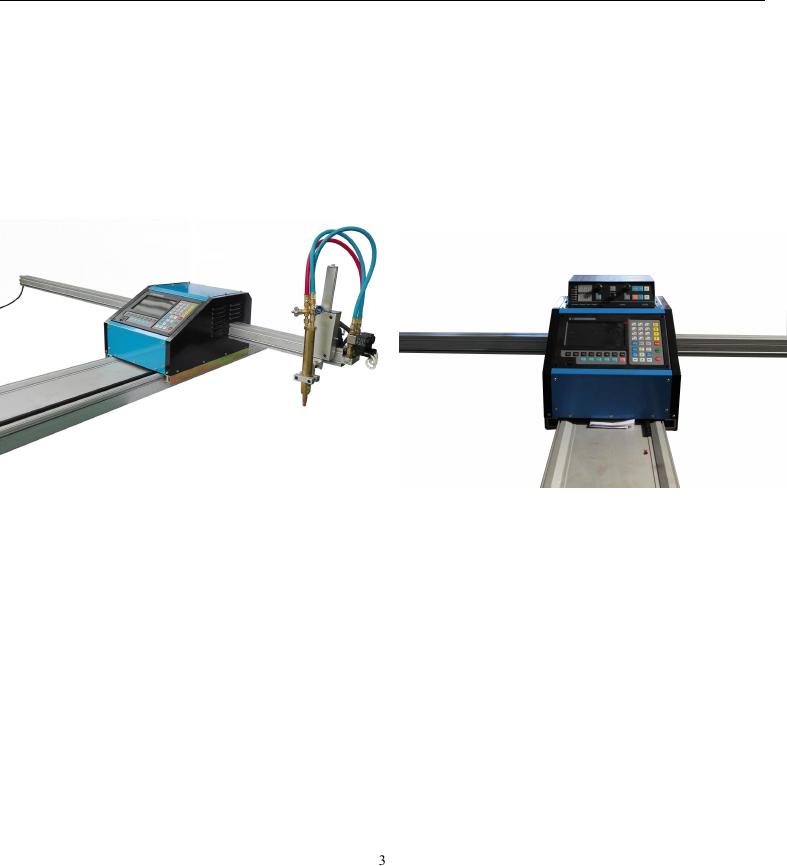

Portable CNC Plasma and Profile Cutting Machines are designed for workshops and industries that need mobility, precision, and cost-effectiveness in one system. Unlike heavy stationary models, these machines combine compact design with robust plasma cutting power, making them ideal for on-site jobs and small to medium-scale operations.

Key features include:

1. Portability with Performance – Lightweight and mobile design allows operators to move the machine easily to different job sites without compromising accuracy.

2. High Cutting Efficiency – Delivers fast cutting speeds and clean edges across a variety of metals including mild steel, stainless steel, and aluminum.

3. CNC Control for Accuracy – Equipped with advanced CNC software for consistent and repeatable results, even with complex profiles and patterns.

4. Dual Cutting Capability – Designed for both plasma cutting and oxy-fuel cutting (in some configurations), making it versatile for different thicknesses and applications.

5. Easy Installation & Setup – Plug-and-play design with user-friendly interface reduces setup time and training requirements.

6. Cost-Effective Operation – Requires less floor space, consumes lower power, and reduces wastage with efficient nesting software.

7. Flexible Configurations – Available with different track lengths, torch options, and power capacities to meet diverse industry requirements.

What makes these machines stand out is their balance of mobility and precision. They are particularly useful in industries where large workpieces cannot be transported easily, making it practical to bring the machine to the material instead.

These machines serve a wide spectrum of industries due to their mobility and flexibility. Unlike traditional fixed cutting systems, portable CNC plasma and profile cutting machines can adapt to various environments and applications.

In the construction industry, they are used for cutting beams, plates, and structural components directly on-site, eliminating the need to transport materials to a fabrication shop. This not only saves logistics costs but also improves project turnaround time.

In shipbuilding and marine applications, where large plates and irregular profiles are common, portable CNC machines offer unmatched convenience. Operators can perform plasma cutting directly in shipyards, handling massive structures without relocation.

Other key applications include:

• Fabrication Workshops – Cutting sheet metal, frames, and complex geometries for machinery and tools.

• Automotive & Heavy Equipment – Manufacturing and repair of chassis, structural components, andagricultural equipment parts.

• Oil & Gas Industry – Cutting pipes, flanges, and heavy plates required in refineries and rigs.

• Railway & Transport – Production and repair of railway wagons, locomotives, and structural sections.

• Custom Metal Works – Ideal for decorative panels, signage, and specialized profiles where mobility and accuracy are critical.

By offering both plasma and optional oxy-fuel cutting capabilities, these machines cater to thin sheet cutting as well as heavy plate applications, making them an all-in-one solution for versatile industries.

Investing in a portable cutting machine requires balancing performance, portability, and cost-efficiency. Metweld machines are built with this balance in mind, making them a preferred choice for industries around the world.

Here’s why Metweld stands out:

• Global-Standard Engineering – Designed and built with strong materials to withstand field operations and tough industrial use.

• Compact & User-Friendly – Small footprint with plug-and-play installation, making it ideal for workshops with limited space.

• Advanced CNC Technology – Accurate motion control ensures clean, repeatable cuts across multiple profiles and thicknesses.

• Versatility in Use – Supports both plasma and oxy-fuel cutting, giving industries the flexibility to handle a wide range of materials.

• Cost-Effective Ownership – Low installation costs, reduced training requirements, and efficient consumable usage mean better ROI.

• Strong After-Sales Support – Training, installation assistance, and ongoing technical service ensure smooth, uninterrupted operations.

Metweld focuses not just on manufacturing machines but on delivering solutions. By offering portable systems that meet global quality standards, the company enables industries to improve productivity without large capital investments.

These machines deliver unique advantages compared to larger stationary systems:

1. Mobility – Move the machine directly to the workpiece, saving time and transportation costs.

2. Space Saving – Requires minimal floor space, perfect for small workshops.

3. Flexibility – Cut flat sheets, angled sections, and profiles with precision.

4. Lower Costs – More affordable than heavy gantry CNC machines while still offering industrial-grade performance.

5. Ease of Use – Simplified controls mean operators with minimal training can run jobs efficiently.

6. Scalability – Suitable for both small custom jobs and larger production runs.

This combination of mobility, efficiency, and cost-effectiveness makes portable CNC plasma and profile cutting machines an excellent choice for industries looking to optimize operations.

| Cutting Thickness | 1.5 mm – 20 mm MS by plasma cutting 1 mm – 18 mm SS by plasma cutting 6 mm – 100 mm MS by gas cutting |

|---|---|

| Model Number/Name | Mini CNC Plasma & Profile Cut |

| Brand/Make | MET ARC |

| Effective Cutting Width | 1.5 – mtr |

| Effective Cutting Length | 3 – 6 mtr |

| Cutting Method | Plasma Or Profile |

Since the year 1982, MET WELD holds a strong presence and offered a comprehensive range of CNC Plasma Cutting Machine and Welding, Cutting Equipment in various sectors of industry.