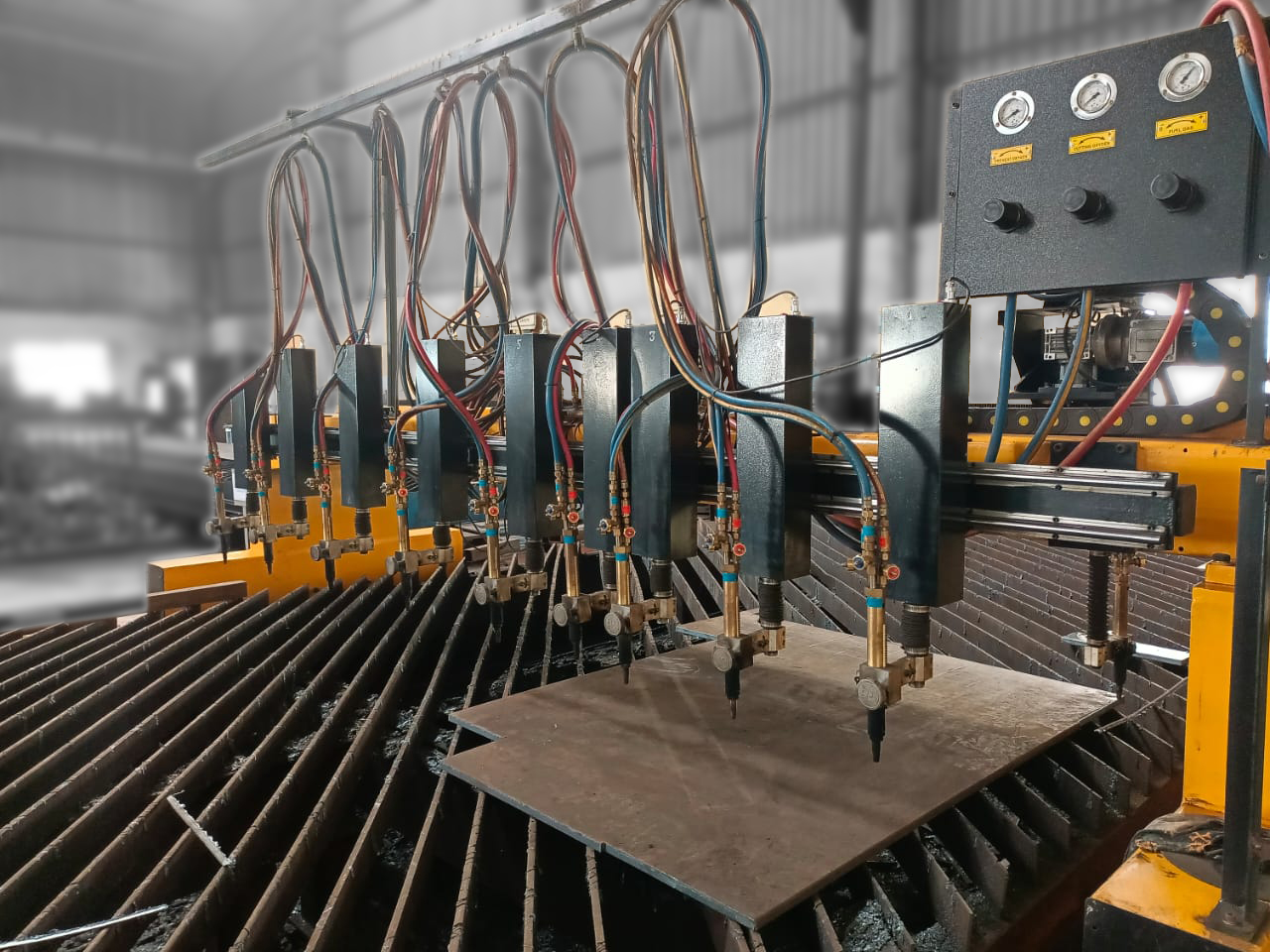

A Multi Torch CNC Plate Cutting Machine is a high-productivity solution designed for industries where speed and efficiency are critical. Unlike standard plasma or oxy-fuel cutters, multi-torch systems allow simultaneous cutting with multiple torches, drastically reducing cycle times and increasing output. These machines are built on rigid frames with advanced CNC controls, ensuring that even when multiple torches are in use, accuracy and consistency are maintained.

They are especially suited for shipbuilding, steel fabrication, construction, heavy machinery, and large-scale manufacturing, where high-volume cutting of thick plates is a routine requirement. By integrating precision CNC control with the power of multiple cutting heads, these machines deliver the perfect balance of speed, versatility, and cost-efficiency.

Metweld’s multi-torch systems are designed to meet the demands of high-volume production environments. The combination of robust build quality and advanced software ensures efficient cutting across large sheets of steel and other metals.

Key features include:

1. Multiple Torch Operation – Equipped with two or more torches, enabling simultaneous cutting of identical profiles for higher throughput.

2. Flexible Torch Configurations – Supports both plasma and oxy-fuel torches, offering versatility across different material thicknesses.

3. High Cutting Speed – Designed to maximize output by cutting multiple lines at once without compromising precision.

4. Sturdy Gantry and Rail System – Provides stability during multi-torch operation, ensuring consistent results across wide plates.

5. Large Working Area – Capable of handling oversized plates, making it suitable for shipyards, fabrication shops, and steel plants.

6. Advanced CNC Controls – Offers high accuracy with repeatability, even in complex geometries.

7. Optimized Nesting Software – Reduces material waste by effectively arranging multiple parts across large sheets.

8. Durability – Built with industrial-grade components that withstand long operational hours and demanding cutting environments.

9. Operator-Friendly Interface – Intuitive controls and CAD/CAM compatibility for quick setup and execution.

10. Optional Bevel Cutting – Some models can perform bevel cutting, allowing preparation of welding edges directly on the machine.

These features make multi-torch CNC systems the ideal choice for industries where speed, precision, and scalability are essential.

The ability to run multiple torches simultaneously makes these machines a preferred choice for high-production industries.

In shipbuilding, where thick plates are used extensively, multi-torch machines can cut multiple sections at once, drastically reducing fabrication time.

In the construction and infrastructure industry, they are used to produce beams, girders, and steel reinforcements quickly and accurately.

Other major applications include:

• Steel Fabrication – High-volume cutting of plates for structural frameworks and machinery.

• Automotive & Heavy Equipment – Producing chassis, frames, and structural parts for trucks, buses, and agricultural equipment.

• Railways – Cutting components for wagons, locomotives, and heavy transport systems.

• Oil & Gas Industry – Manufacturing large plate-based components, flanges, and support structures for rigs and pipelines.

• Energy Sector – Producing parts for power plants, wind turbines, and renewable energy systems.

• Metal Service Centers – Offering batch cutting services for different industries that require quick turnaround.

The multi-torch advantage ensures that these machines not only increase production speed but also improve efficiency in bulk cutting jobs.

Metweld designs and manufactures machines that combine productivity, precision, and durability, making them ideal for industries operating at scale.

Key reasons to choose Metweld:

• Productivity-Focused Design – Multi-torch capability significantly reduces production time by cutting multiple profiles simultaneously.

• Engineering Strength – Heavy-duty gantry and frame construction ensures accuracy even under continuous operation.

• Versatile Configurations – Machines can be customized with plasma, oxy-fuel, or hybrid torch setups.

• Advanced Automation – CNC controls with intuitive software simplify programming and ensure repeatable accuracy.

• Optimized Material Use – Nesting software reduces waste, increasing cost efficiency per part.

• Scalability – Suitable for both medium and large-scale industries with varied production needs.

• Operator-Friendly Systems – Touchscreen interfaces and CAD/CAM compatibility ensure easy operation and quick learning curves.

• End-to-End Support – Metweld provides installation, training, service, and spare parts, ensuring smooth operations for customers worldwide.

By choosing Metweld, industries gain access to globally benchmarked CNC cutting solutions that guarantee reliability in high-demand environments.

The biggest advantage of multi-torch machines is their ability to cut multiple profiles simultaneously, but the benefits extend much further:

1. Increased Production Speed – Multiple torches working at once drastically reduce cycle times.

2. Lower Cost per Part – Efficient cutting reduces material waste and operational costs.

3. Flexibility in Cutting – Ability to cut a variety of metals and plate thicknesses using plasma or oxy-fuel.

4. High Accuracy at Scale – Maintains precision even during large-scale production.

5. Durability – Built to withstand long shifts and heavy workloads in demanding environments.

6. Customization – Machines can be configured for specific industry requirements, including bevel cutting options.

These advantages make them essential for industries looking to scale up production without compromising on quality.

| Process | Gas Cutting, Plasma Cutting |

|---|---|

| Effective cutting width | 2.5 m to 5 m |

| Cutting Length | 3 m to 24 m |

| Positioning speed | 0 – 12,000 mm/min |

| Cutting thickness | 1.5 mm – 20 mm MS by plasma cutting 1 mm – 18 mm SS by plasma cutting 6 mm – 150 mm MS by gas cutting |

Since the year 1982, MET WELD holds a strong presence and offered a comprehensive range of CNC Plasma Cutting Machine and Welding, Cutting Equipment in various sectors of industry.