Metweld is a renowned name in the manufacturing of CNC plasma cutting machines, delivering advanced cutting solutions for industries such as metal fabrication, construction, and automotive. Our plasma cutting machines are engineered for precision, efficiency, and durability, making them the preferred choice for businesses seeking reliable cutting technology. If you are looking for a high-quality CNC plasma cutter, Metweld offers customized solutions tailored to your requirements.

Our CNC plasma cutting machines are designed to meet the demands of modern industries. Here’s what sets Metweld apart:

Metweld’s plasma cutting machines are known for their ability to cut through a variety of metals, including mild steel, stainless steel, and aluminum, with remarkable accuracy. This precision helps reduce material wastage and enhances the quality of the final product.

The advanced CNC controller in our CNC plasma cutting machines ensures ease of use, allowing operators to program and manage cutting parameters effortlessly. This results in faster setup times and improved productivity.

Our plasma cutting machines are built with premium materials to ensure long-term durability. Designed to handle rigorous industrial applications, they maintain peak performance under heavy workloads.

Metweld’s CNC plasma cutters deliver fast and efficient cutting speeds without compromising precision. This makes them ideal for industries that require high productivity and tight deadlines.

Our CNC plasma cutting machines are compatible with popular CAD/CAM software, making it easy to integrate into your existing workflows. This feature simplifies design processes and ensures efficient cutting operations.

Metweld’s CNC plasma cutting machines are versatile and widely used in various industries:

Our CNC plasma cutters help fabricators achieve clean, accurate cuts for creating metal components, structures, and parts.

The precision offered by our plasma cutting machines makes them ideal for manufacturing automotive parts, custom brackets, and sheet metal components.

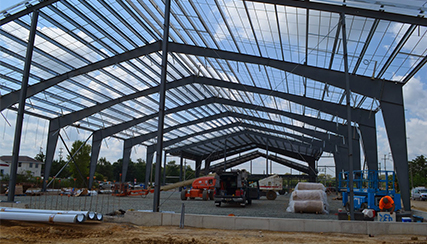

Metweld’s CNC plasma cutting machines in Ahmedabad are widely used for cutting materials in construction projects such as frameworks, bridges, and architectural designs.

For artistic and decorative projects, our CNC plasma cutters enable intricate and detailed designs, ensuring smooth finishes for high-quality results.

As leading CNC plasma cutting machine manufacturers, we offer machines tailored to meet your specific needs. Whether you need a compact system or a high-capacity machine, we have you covered.

Our plasma cutting machines are designed to optimize energy consumption, reducing operational costs while maintaining high-quality output.

From installation to ongoing maintenance, Metweld provides comprehensive support to ensure your CNC plasma cutting machine operates at its best.

Known for reliability and performance, Metweld is a trusted provider of CNC plasma cutters for industries across Ahmedabad and other regions.

If you are looking for a reliable CNC plasma cutting machine in Ahmedabad, Metweld is your trusted partner. Our high-performance machines are built to deliver precision, speed, and reliability, helping you meet your cutting needs efficiently.

CNC Plasma Cutting Machines offer several advantages that make them a preferred choice in industries where speed and heavy-duty cutting are vital.

• Cutting Speed – Plasma systems are significantly faster than oxy-fuel and mechanical cutting methods, especially on medium-thickness materials.

• Thick Plate Capability – Unlike laser cutting, plasma machines excel at handling thicker plates economically.

• Operational Flexibility – Capable of cutting flat sheets, angled cuts, and even curved or cylindrical shapes with add-on systems.

• Lower Equipment Cost – Compared to laser machines, plasma cutters generally come at a lower upfront investment, making them accessible for many industries.

• Durability in Harsh Conditions – Built to withstand dust, heavy usage, and long operational hours.

For industries that prioritize speed, cost-efficiency, and heavy-duty performance, CNC plasma cutting is one of the most practical solutions.

Ready to enhance your cutting operations? Choose Metweld’s advanced plasma cutting machines for unmatched performance and durability. Contact us to learn more about our range of CNC plasma cutting machines and how we can help your business succeed.

| Specification | Details |

|---|---|

| Cutting Capacity | Maximum cutting length and width depending on the model (up to 50mm thick). |

| Drive System | High-precision linear and servo motors for smooth movement across axes. |

| Positioning Accuracy | High-precision positioning for consistent, accurate cuts with minimal errors. |

| Cutting Speed | High-speed cutting, varying based on material type and thickness. |

| Input Power | Operates on standard industrial power supply, available in various voltage/amperage options. |

| Torch Control | Advanced automatic torch height control system for optimal distance from material. |

| Gas Supply | Compatible with compressed air, oxygen, nitrogen, depending on material and application. |

| Airflow | Optimized airflow requirement for efficient cutting and clean results. |