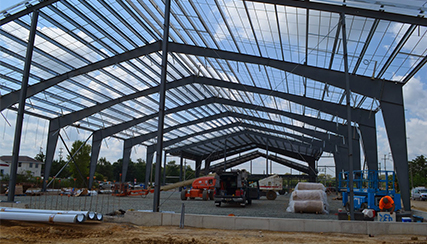

Pre-Engineered Buildings (PEB) rely on accurate steel cutting and fabrication to achieve structural strength, cost efficiency, and rapid project completion. At the heart of this process lies CNC Plasma Cutting Technology — the modern solution for fast, precise, and economical cutting of steel plates, beams, and components used in PEB construction.

Metweld’s advanced CNC Plasma Cutting Machines empower fabricators, builders, and contractors to meet demanding PEB standards by ensuring every column, rafter, and gusset plate is cut with unmatched accuracy.

In PEB fabrication, thousands of components — from base plates and purlins to trusses and bracing elements — must align perfectly during on-site assembly. Even a few millimeters of deviation can cause misalignment or structural stress.

By automating the cutting process through Computer Numerical Control (CNC), plasma systems provide:

• High Precision: Consistent dimensional accuracy for flawless fitment.

• Repeatability: Identical output in large production runs.

• Speed: Rapid processing of medium-to-thick steel plates.

• Efficiency: Optimized nesting to reduce material waste.

• Reliability: Stable arc performance and minimal rework.

This blend of precision and productivity helps PEB manufacturers deliver superior quality structures within shorter deadlines.

CNC plasma systems maintain tight cutting tolerances even on 50 mm thick plates, ensuring all parts — columns, rafters, base plates — fit seamlessly during erection.

Automated torch movement and faster piercing speeds shorten cutting cycles, enabling large-scale output with minimum downtime.

From simple base plates to complex gusset geometries, CAD/CAM integration allows precise execution of any PEB design without manual marking or layout errors.

Plasma systems combine lower capital cost with lower consumable usage compared to laser or oxy-fuel setups, giving the best cost-to-output ratio for PEB manufacturers.

Clean, burr-free edges ensure stronger weld joints, reducing grinding and secondary finishing time.

Suitable for fabrication shops handling custom industrial sheds as well as high-volume PEB production units.

CNC Plasma Cutting Machines from Metweld are used at multiple stages of PEB manufacturing:

• Structural Members: Cutting columns, rafters, and purlins with accurate profiles for perfect alignment.

• Base & End Plates: Precise drilling and contour cutting for bolted and welded joints.

• Gusset Plates & Bracings: Custom shapes to enhance structural strength and stability.

• Roof & Wall Components: Creating secondary members and support brackets.

• Custom Fabrications: Special panels, canopies, mezzanine structures, and decorative metalwork.

This versatility allows a single CNC plasma machine to handle the entire spectrum of PEB steel fabrication requirements.

| Parameter | CNC Plasma Cutting | Manual / Oxy-Fuel Cutting |

|---|---|---|

| Accuracy | ± 0.2 mm | ± 2 mm or more |

| Speed | 3–5 times faster | Slow |

| Edge Quality | Smooth, ready to weld | Rough, needs finishing |

| Material Use | Optimized via nesting | High waste |

| Cost Per Part | Low (automation) | High (labor + rework) |

| Safety & Consistency | Fully automated | Manual risk and variability |

CNC Plasma Cutting offers the best balance of speed, cost, and quality, making it the preferred fabrication technology for PEB manufacturers.

Metweld provides a complete range of CNC Plasma Cutting Machines tailored to PEB applications:

• Table Type CNC Plasma Cutters – Compact, accurate, and ideal for sheet and medium-plate cutting.

• Gantry Type Plasma Cutting Machines – For large-format plates and heavy-duty structural fabrication.

• Multi-Torch Systems – Enable simultaneous cutting of multiple profiles to accelerate throughput.

• Pipe & Flange Cutting Machines – For cutting round pipes, flanges, and structural tubing used in PEB pipelines and frameworks.

• Portable CNC Profile Cutting Machines – Lightweight and versatile, perfect for on-site PEB work.

All Metweld machines feature advanced CNC controls, efficient nesting software, and industrial-grade torches for consistent performance in high-volume operations.

• Precision Engineering: Designed to handle demanding industrial workloads with consistent accuracy.

• Global Standards: Built to international quality norms for long-term reliability.

• Automation Integration: CAD/CAM compatibility streamlines your design-to-production workflow.

• Lower Operating Cost: Efficient power usage and durable consumables reduce production expenses.

• Comprehensive Support: Installation, training, spare parts, and after-sales service from Metweld’s technical team.

With Metweld, PEB manufacturers gain a trusted partner who understands the importance of accuracy, timely delivery, and machine longevity in large-scale projects.